A Self Propelled Modular Transporter (SPMT) is a platform vehicle with a large array of wheels on the bottom. They are used for transporting massive objects such as bridges, oil refining equipment, huge motors, large bridge sections, and other objects that are too big or heavy for trucks. These vehicle may also be called a Self Propelled Modular Trailer.

SPMTs are increasingly used in the construction and oil industries, and have been recently begun to be used to replace bridge spans, in the United States and Europe, and more recently, Canada.

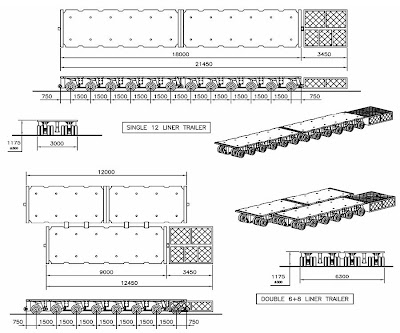

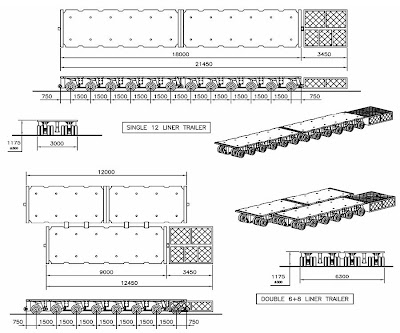

A typical SPMT can have a grid of several dozen computer-controlled wheels, all individually controllable and steerable, in order to evenly distribute weight and steer accurately. Each individual wheel can swivel independently from other wheels, to allow the SPMT to turn, move sideways, or even spin in place. Some SPMTs allow each wheel to telescope independently of each other, so that the load can be kept flat and evenly distributed while moving over uneven terrain. As SPMTs often carry the world's heaviest loads on wheeled vehicles, they are very slow vehicles, often moving at under one mile per hour while fully loaded. Some SPMTs are controlled by a worker with a hand held control panel, while other SPMTs have a driver cabin. In addition, multiple SPMTs can be combined to transport massive building-sized objects.

SPMTs have also been featured on Discovery Channel during shows involving engineering.

Normal load/axle-line: 22.5tons or 32.5tons.

Drive type: Hydrostatics

Steering type: Normal linkage steering (first wheel max. steering angle 55-60degree) or independant steering (also called e-multi steering. all wheels +/- 115 to 135degree or even 360degree steering).

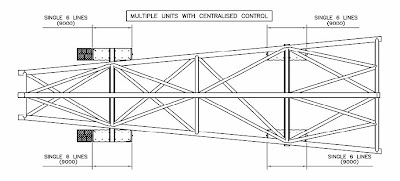

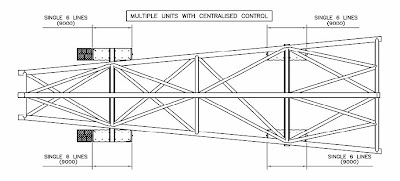

Different Combination Mode of SPMT

Multiple combination with central remote control